Magnesium

Magnesium, which also goes by the chemical symbol Mg, is a fairly common metal in our everyday lives and in nature, much like aluminium. It is the eighth most abundant element on the Earth’s crust. It rarely occurs naturally in its metallic form, which is why a chemical process — mainly electrolysis — is used to obtain this metal.

Given its mechanical properties, once alloyed, it is perfect for the construction of resistant and lightweight pieces, hence why its use has been widespread in the automotive and aerospace industries since the beginning of the 20th century.

It has a lower density than aluminium at only 1.73 g/cm3, and its melting point is 650°C, the lowest of all alkaline earth metals.

In MotoGP, magnesium can be found in some engine parts, but its most common and visually striking use can be found in the bike’s rims. The difference in weight between rim sets manufactured with aluminium and cast magnesium is significant: the pair only weighs 7.4 kg, virtually half of the weight of aluminium die-cast rims.

For optimal properties, it should be alloyed with other elements such as aluminium, zinc, zirconium, and manganese, because magnesium alone lacks many of the properties that can be obtained through alloys.

Rims are manufactured using hot-forge techniques. This process requires temperatures within a range of 250 to 450°C, depending on the shape and alloy. A press with forces ranging between 600 to 13 000 tonnes is also needed. The process should be carried out slowly and progressively, repeating the pressing step several times. This is done to prevent cracks from forming in the metal, although some press models are now able to carry out the entire process more swiftly.

Once the pieces have been forged, they are given the final mechanical finishing touches with CNC machines, and later undergo different thermal and chemical treatments to ensure peak performance.

Magnesium isn’t just important for peak performance in MotoGP. The human body makes good use of magnesium too, as well as plants, and it can be found in many nuts, cereals, and legumes.

What’s more, every time you see a flash of white fireworks, you can thank magnesium for that brilliant glow. If you are into climbing or weight lifting, that’s magnesium you are rubbing on the palms of your hands to prevent slipping. And if you have taken a survival lighter into the woods with you, you can bet that it has a magnesium bar inside that gives off intense sparks when rubbed.

Lightweight materials for MotoGP

Titanium

Titanium is a metal with the chemical symbol Ti, and is also a relatively common element: the ninth most common in the Earth’s crust. It was named by Martin Heinrich Klaptroth after the Titans in Greek mythology.

As is the case with other elements, titanium does not occur naturally and is obtained through refining, as it is found in other mineral deposits such as rutile and ilmenite. Funnily enough, one of the elements that can be used in the refining process is magnesium.

It has a density of 4.5 g/cm3, which makes it the heaviest of the lightweight metals. Its high resistance makes it the ideal candidate for the aerospace, medical, industrial, and military industries because it outperforms steel (except in the case of specific alloys).

It is highly resistant to corrosion and wear, and has a high melting point: 1668°C. It has fairly low electrical and thermal conductivity, however, its strength suffers slightly when it is heated above 430°C.

Although it is possible to find practically pure titanium being used, for industrial purposes it is more common to create alloys with other metals such as aluminium, vanadium, molybdenum, or manganese.

Titanium parts are very expensive given how difficult it is to obtain and process them. Extremely precise conditions are required in certain titanium alloys when working, welding, or moulding this element in order to avoid breaks or contamination.

Some titanium alloys display incredible tensile strength, which is why it’s an ideal element for use in competitive automotive parts. However, MotoGP regulations forbid its use in specific parts, such as the frame, swingarm, axles, and handlebars, as well as some parts of the shock absorbers.

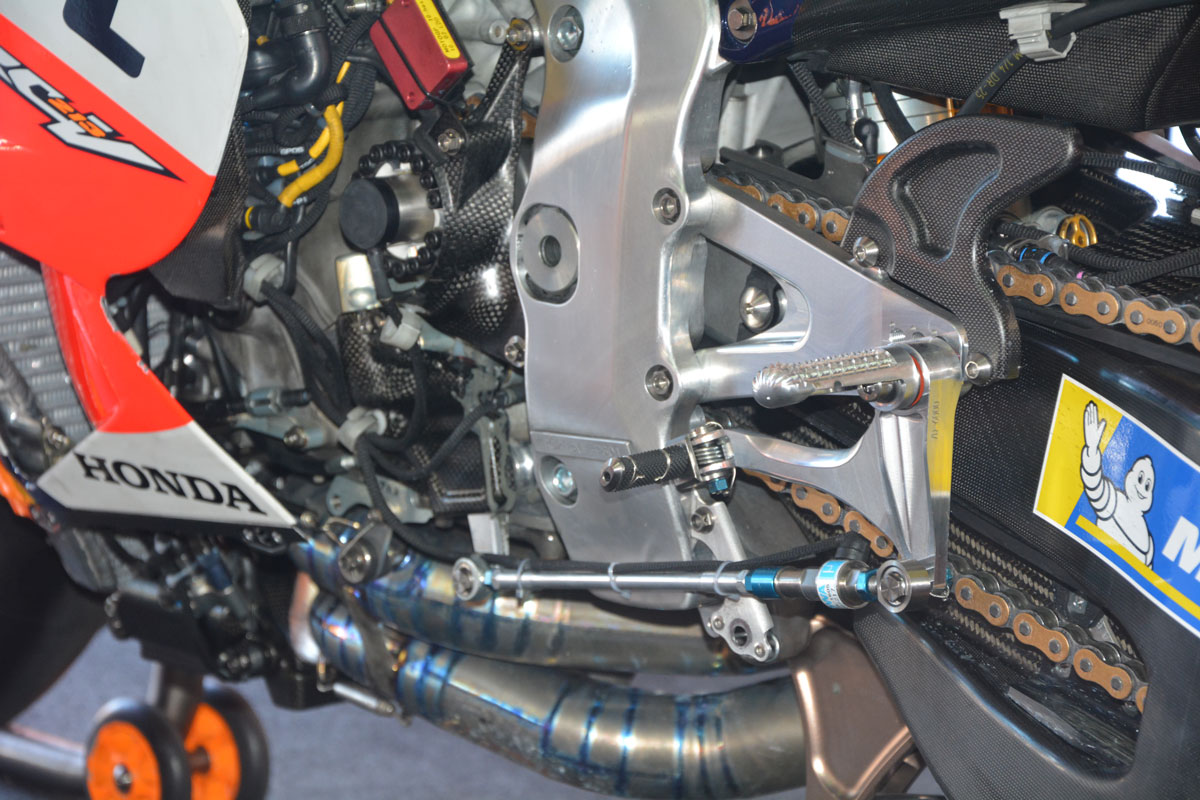

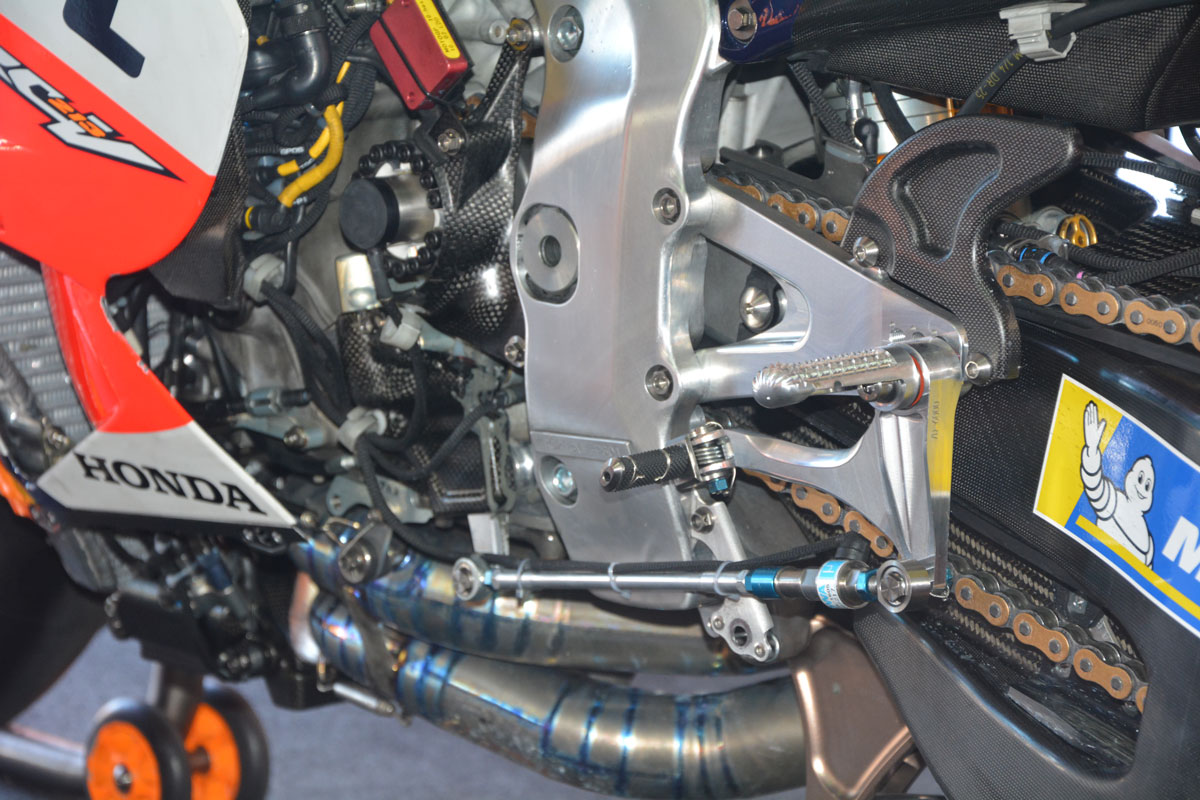

There are, however, many components that are lucky enough to be able to benefit from titanium alloys, for example, screws and fasteners of any of the aforementioned parts. This is also applicable to several components in the braking system, exhaust pipes, and internal engine parts, such as valves.

In other areas, titanium can be found in medical or dental prostheses since it is biocompatible. The most technologically advanced use of titanium is employed by SpaceX, which uses big titanium meshes on its Falcon9 rockets to guide them back into the atmosphere. On a different note, the outer coat of the Guggenheim museum in Bilbao is made from titanium, as well as the fuselage on the retired reconnaissance aircraft Lockheed SR-71 Blackbird, which could fly at speeds of over 3500 km/h!

Although the use of these materials is limited in MotoGP regulations, their use in competitive racing is essential to get the most out of the Honda RC213V. Thanks to these lightweight and high-strength materials — titanium and magnesium — our riders are able to break their records time and time again on the World Championship tracks.

Join Us

Join Us  Join Us

Join Us